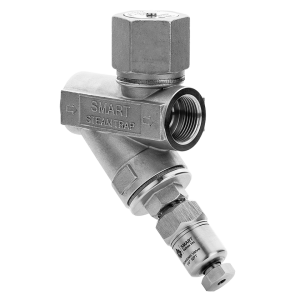

The SMART SVT DN15/20 Venturi Steam Trap is designed for multipurpose applications from mainline drainage and trace heating, through small to medium size heat-exchanger process applications. The trap has integrated strainers and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and integrated strainers are via the top and bottom caps.

SMART VALVES STEAM TRAPS

Smart Valves Inc, Steam Trap Manufacturer & Supplier of high quality Venturi Steam Traps, Custom Design Steam Traps, Integrated Blowdown Valves & Steam Trap Insulation Jackets. 20 year Guarantee, 90 day product trial available. US Designed. Steam Trap Installation, Training & Maintenance Services

Our Products

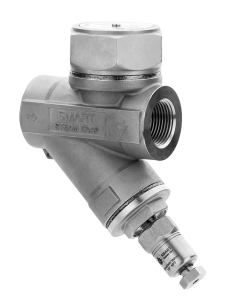

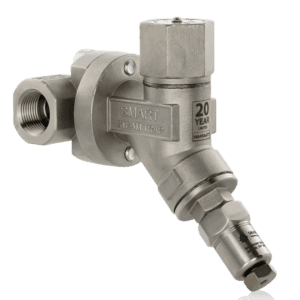

The SMART SVT DN25 Venturi Steam Trap is designed for multipurpose applications from mainline drainage and trace heating, through small to large size heat-exchanger process applications. The trap has an integrated bottom strainer with 25% increased capacity and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and strainer are via the top and bottom caps. SMART SVT™ model steam trap also comes with an integrated blowdown valve for periodic cleaning of the filter.

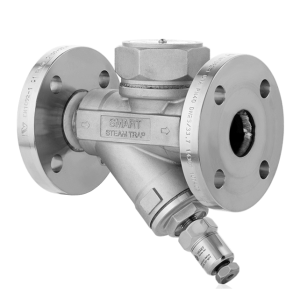

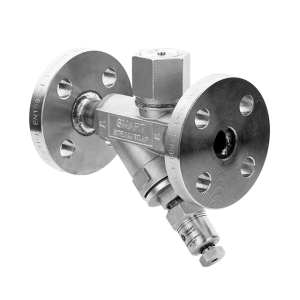

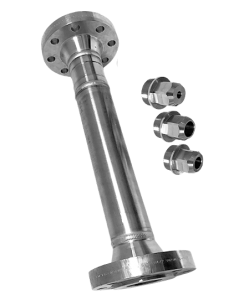

The SMART SVT-F DN25 Flanged Venturi Steam trap is designed for multipurpose applications from mainline drainage and trace heating, through small to medium size heat-exchanger process applications. The trap has integrated strainers and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and integrated strainers are via the top and bottom caps. Access to the venturi insert and integrated strainers is via the top and bottom caps.

The SMART SVT-F DN15/20 Flanged Venturi Steam trap is designed for multipurpose applications from mainline drainage and trace heating, through small to medium size heat-exchanger process applications. The trap has integrated strainers and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and integrated strainers are via the top and bottom caps.

The SMART SVT™ UNI is a universal connector venturi steam trap intended to work as a distribution (drip leg) steam trap for draining condensate from main steam lines and as a trace heating steam trap to drain condensate from trace heating lines. The trap has integrated strainers and a removable venturi insert. The SVT UNI model steam trap comes in 3 standard sizes: standard, medium, and large capacity, and it can be mounted on most of the 2 bolt quick-release universal connector bases. For additional capacity changes outside the 3 standard sizes, the trap can be resized with optional venturi inserts for extra small or extra-large capacity conditions. The body of the steam trap does not have to be removed from the line for maintenance purposes. The venturi insert and strainers can be simply accessed via the top and bottom caps. SMART SVT™ UNI model steam traps also come with an integrated blowdown valve for periodic cleaning of the bottom filter.

The SMART STC DN15-DN50 Venturi Steam Trap is designed for medium to high capacity industrial process applications with a wide range of pressure differential. The applications include heat exchangers, reboilers, process columns, etc with capacity up to 65 000lbs/hr or 30 000kg/hr. It is recommended that a strainer is installed upstream of the trap.

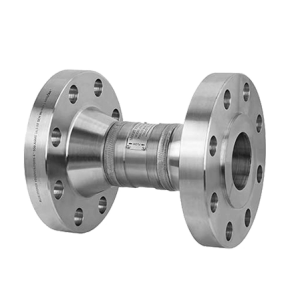

The SMART STC-F DN25-DN100 Flanged Venturi Steam Trap is designed for high capacity industrial process applications with a wide range of pressure differential. The applications include heat exchangers, reboilers, process columns, etc with capacity up to 100 000 kg/hr or 220 000 lbs/hr. The SMART STC-F™ Flanged Venturi Steam Trap has a removable venturi insert. It is recommended that a strainer is fitted upstream of the trap.

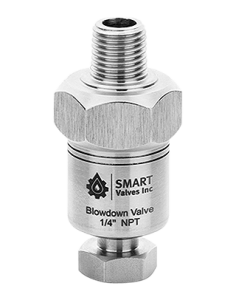

SMART Blowdown Valve SBV-20 is an integral component designed to be fitted into the following range of SMART Steam Traps to Bleed off the dirt and scale of the bottom strainer screen: SVT 15/20, SVT25, SVT-F 15, SVT-F 20, SVT-F 25, SVT-FL 50, and SVT-UNI. SMART Blowdown Valve SBV-20 is an optional component to our manufactured SMART Steam Traps product models with built-in strainers to make maintenance more convenient. When SMART Steam Trap is assembled with an integrated blowdown valve, preventative maintenance (PM) can be performed at any time and under the system pressure. It only takes 1 minute per unit to perform PM compared to 10 to 15 minutes if the trap is cleaned manually by taking it apart. SMART Blowdown Valve SBV-20 is the only product outside the SMART Steam Trap product range with a 20-year warranty.

SMART Steam Trap Custom-Built is a service package to order custom-built steam traps designed and assembled for all process applications. SMART Steam Trap Custom-Built can be requested in different grades of stainless steel, a wide range of sizes and pressure classes, and flanged ends extended to fit exactly in the same place where the current steam trap is installed. Since we are flexible in our approach, we can offer cost-effective solutions as per your requirements, no matter if it’s a single steam trap or multiple orders. We believe that time is the essence when it comes to replacing process steam traps in a manufacturing facility. Therefore, we strive to deliver your order from the concept to the finished product in less than 4 weeks by delivering all orders worldwide via air express shipping in 3-5 days to any country.

This is Our Story

About us

Our SMART Steam Trap’s technical design advantage is set up to improve industries worldwide, but our main priority is to give you full access to technical support directly from the manufacturer while also providing you with reliable support through your local dealer.

READ more

Our Services

Read more >>

The commissioning service includes:

- Review of Installation Design.

- Testing each installed unit with thermal imaging equipment, and optimize if necessary.

- Showing how to perform preventative maintenance (PM) on the valves.

- Providing technical guidance and instruction to the operating personnel.

- Answering any questions you need about our products.

- Sending a report with each steam trap temperature readings and our assessment for performance.

- Suggestions on other improvements based on technician observations during the system inspection.

To request commissioning, simply include the commissioning service with your purchase order when ordering the products from our partners or ask us.

SMART Valves Inc. turn-key service includes:

- Steam system energy audit to identify failed steam traps.

- SMART Steam Trap and SMART Valves installation.

- Implementation of other energy conservation measures identified during an energy audit.

- Project Management, oversight of subcontractors and vendors.

- Startup, commissioning, and training.

- After-sales yearly steam valve maintenance program.

The benefits from PM program can be:

- Cost savings

- Decreased emergency maintenance calls

- Extended life of piping and other components

- Increased steam systems energy efficiency

- Increased heat transfer efficiency

- Reduced water hammer

- Reduced steam usage

- Reduced back-pressure in the return line

- Reduced heat exchanger bundle and coil issues.

Since we are not limited by size or materials and are flexible in our approach, we can provide a wide range of design options in our products. We understand that every steam system is a little different due to different system conditions and needs. Therefore, through the SMART Steam Trap Custom Built service, we are able to offer a cost-effective solution per your requirements, irrespective of whether it's a single steam trap or multiple orders. We believe that time is the essence when it comes to replacing process steam traps in a manufacturing facility. Therefore, we strive to deliver your custom-built order from design concept to the finished product in less than 4 weeks by delivering all orders worldwide via air express shipping in 3-5 days to any country

Just send us your requirements and we will make one of a kind steam trap and deliver it for you to test. When you select SMART Steam Trap Custom Built service, you can expect that the product will be made just for you and as per your requirements.

Our Clients

Brands that trust us