Description

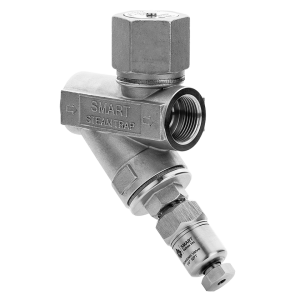

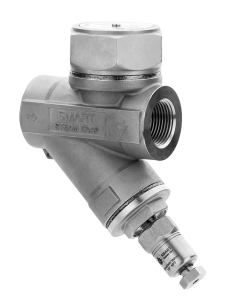

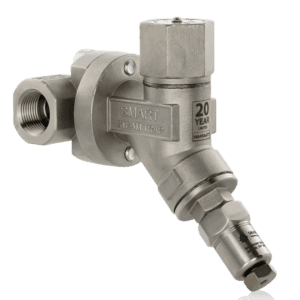

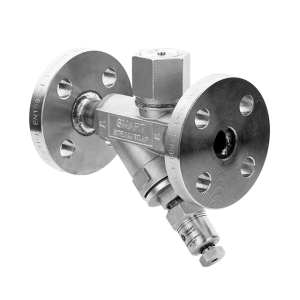

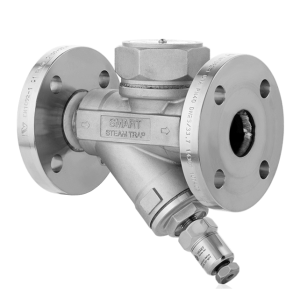

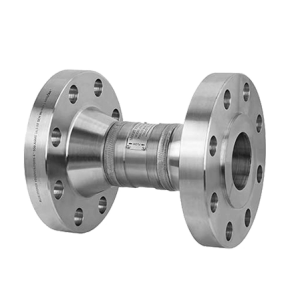

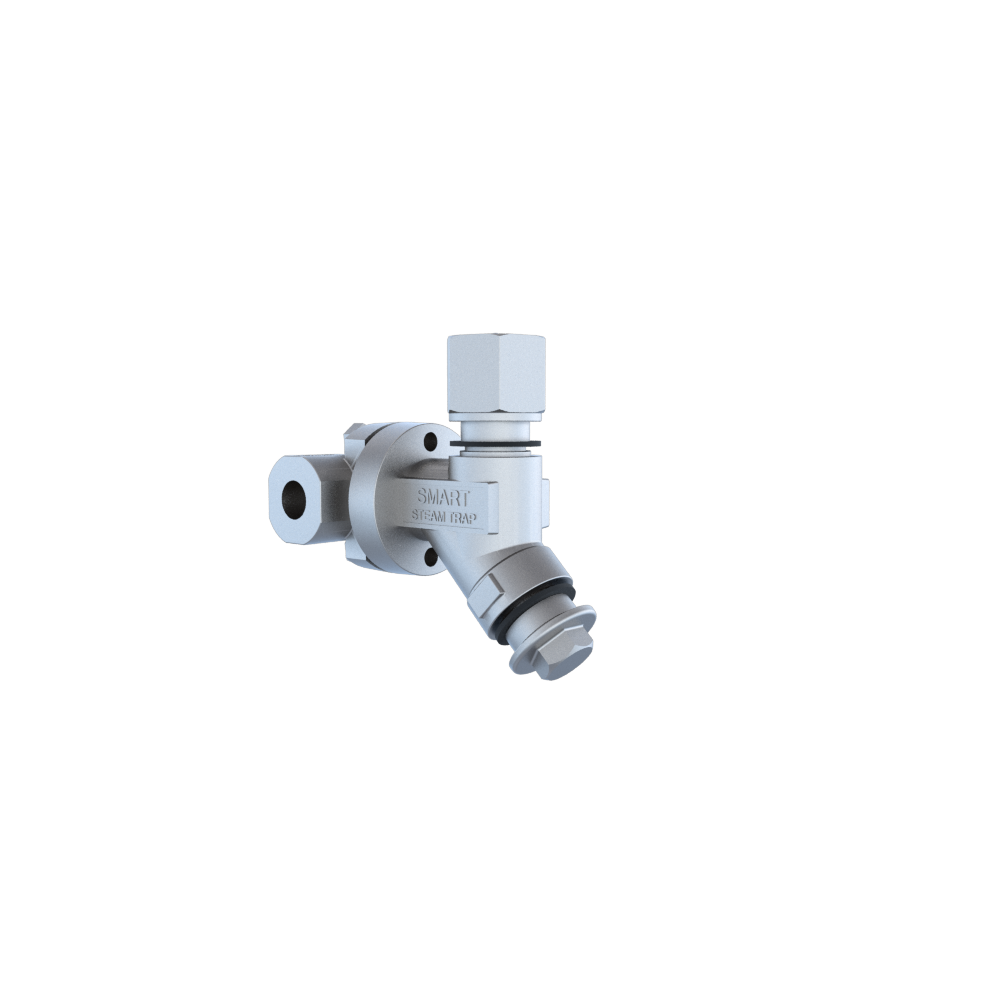

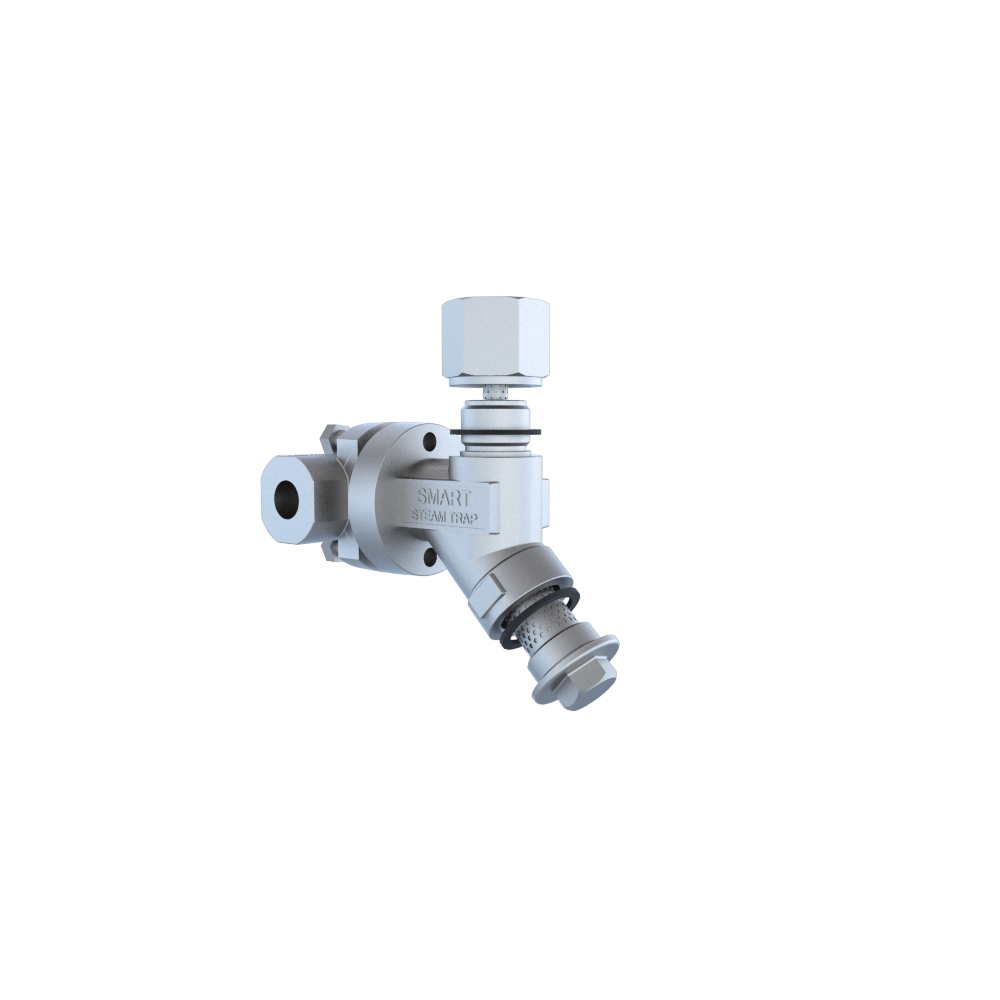

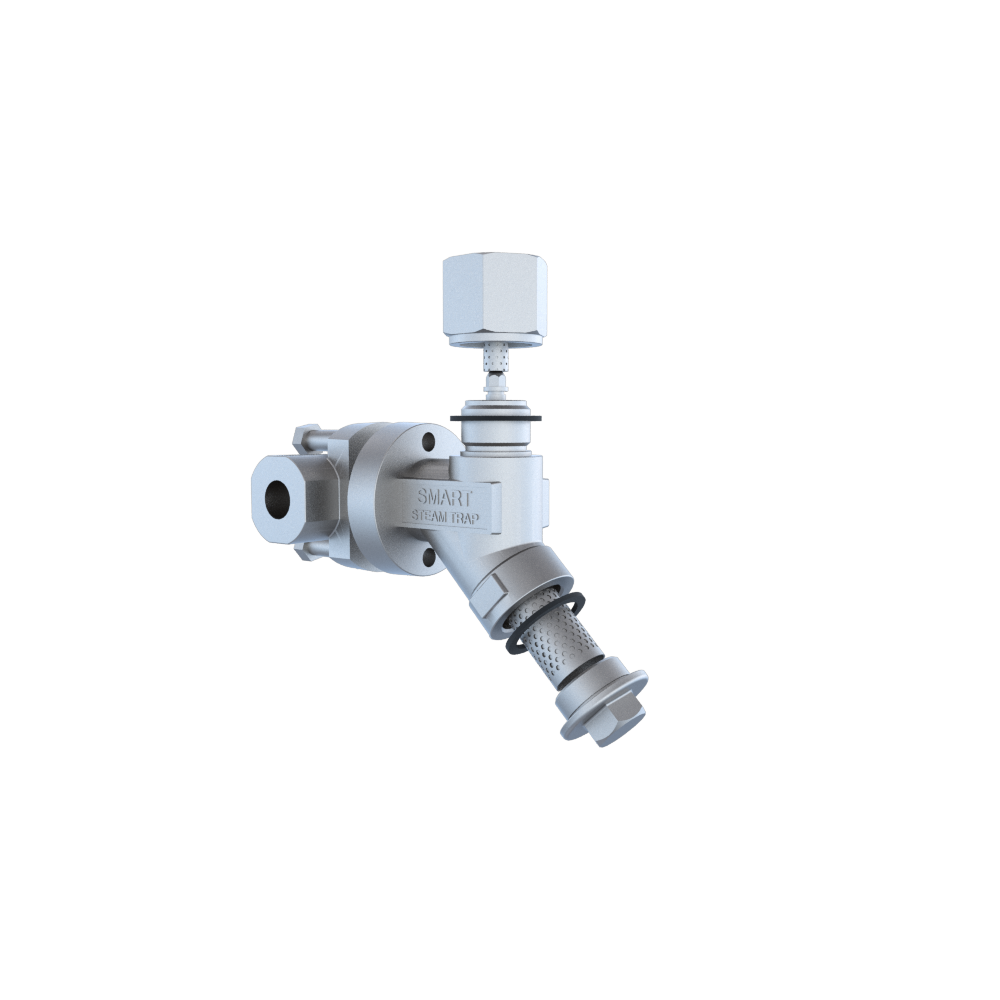

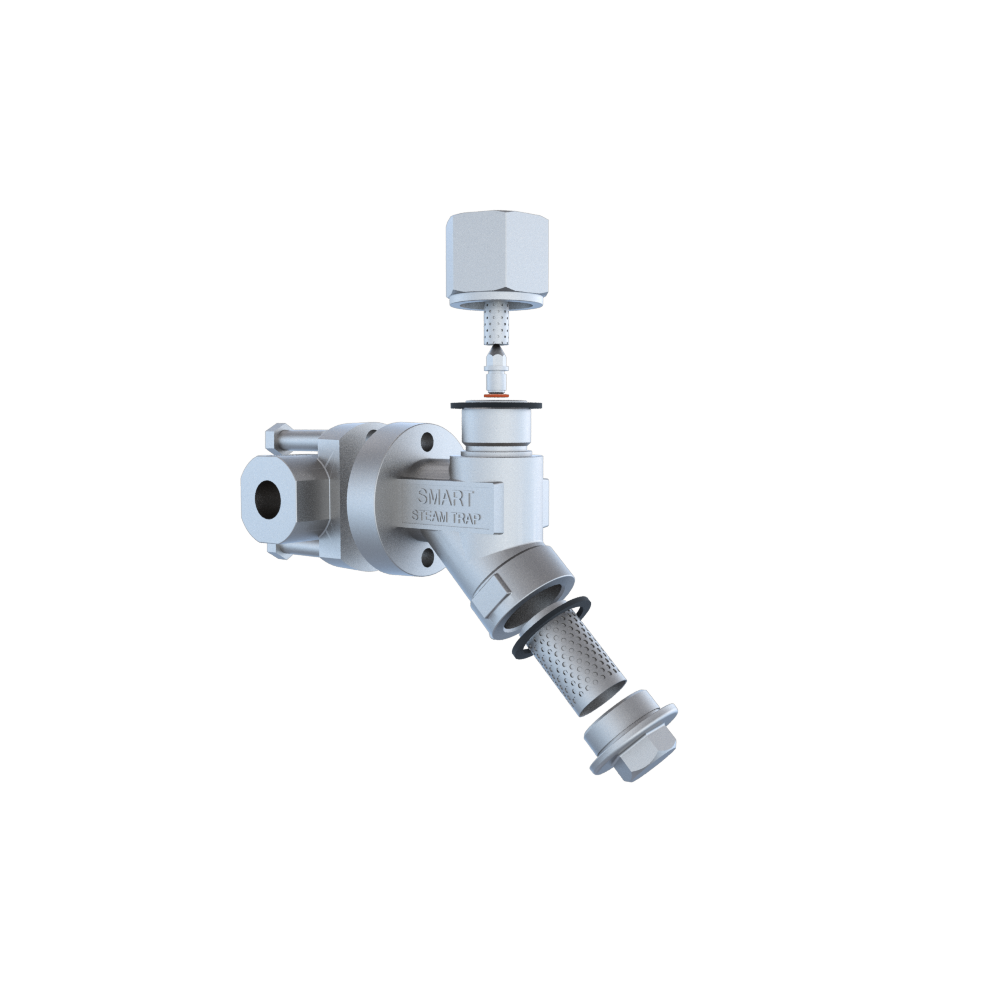

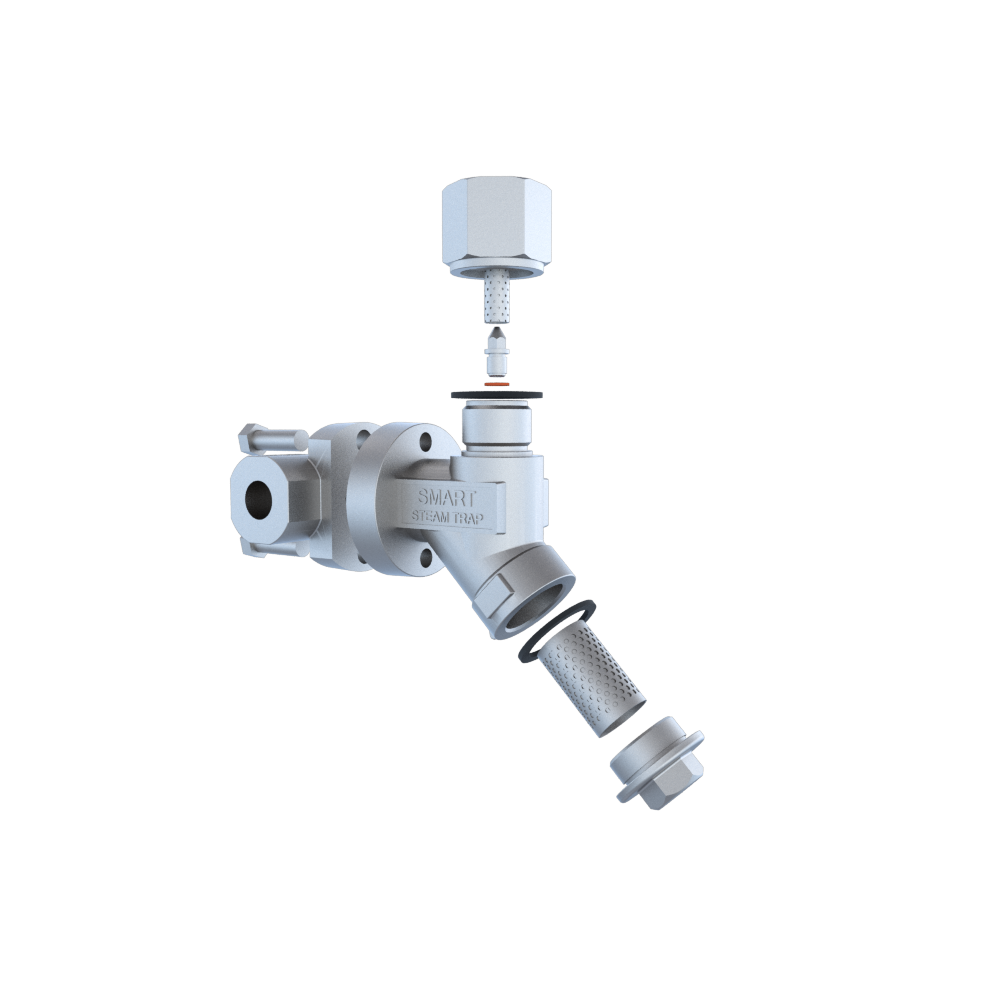

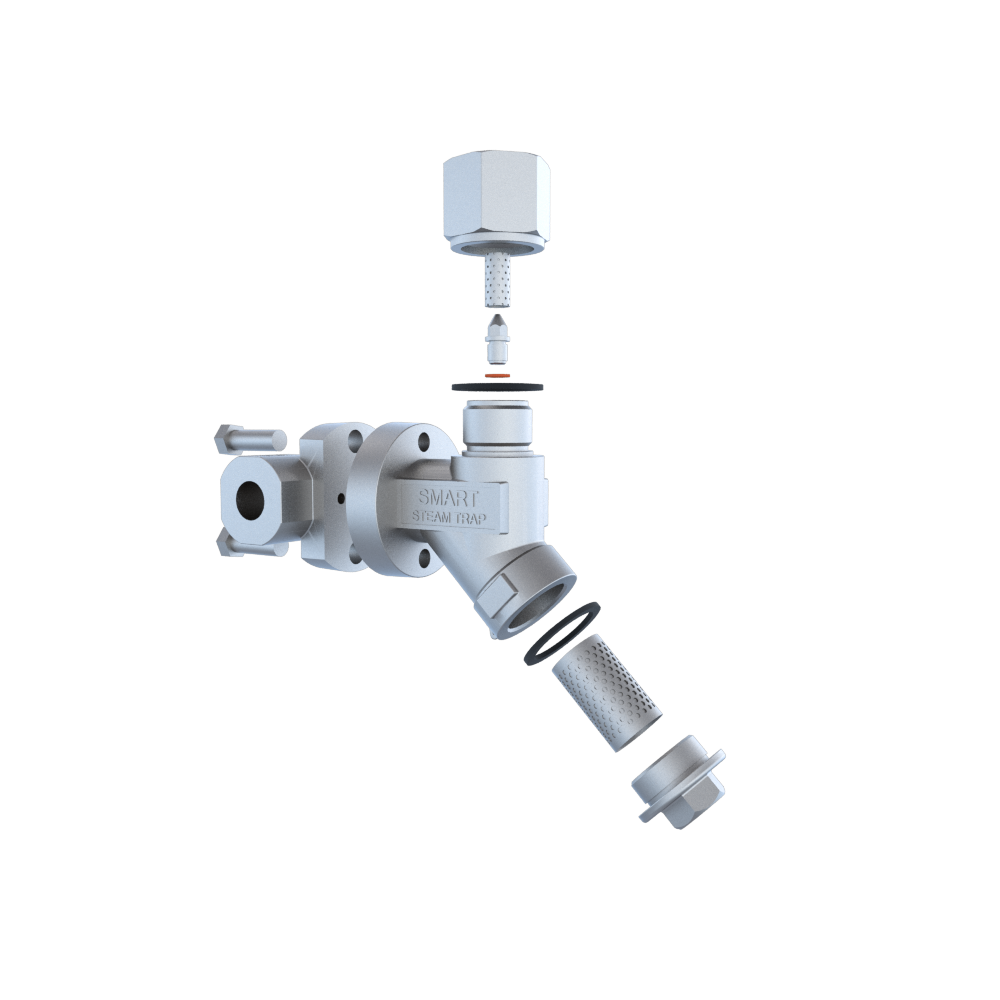

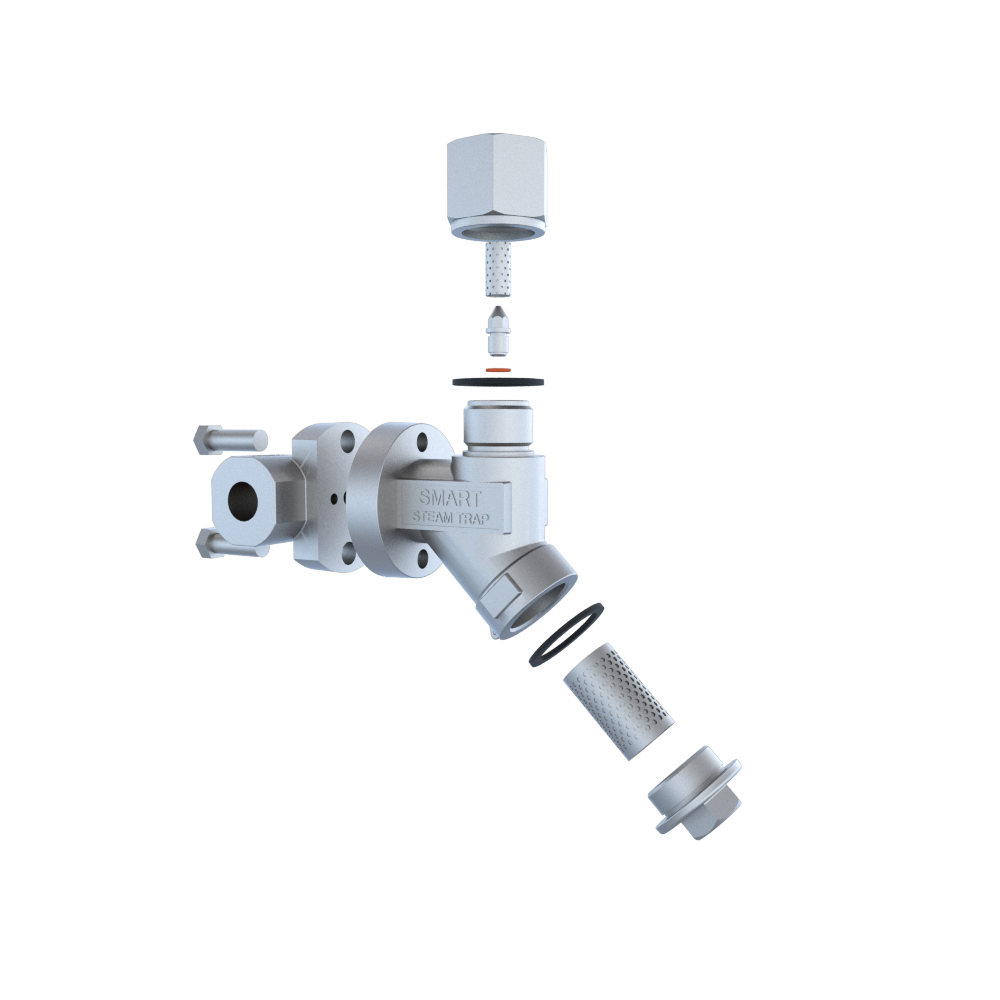

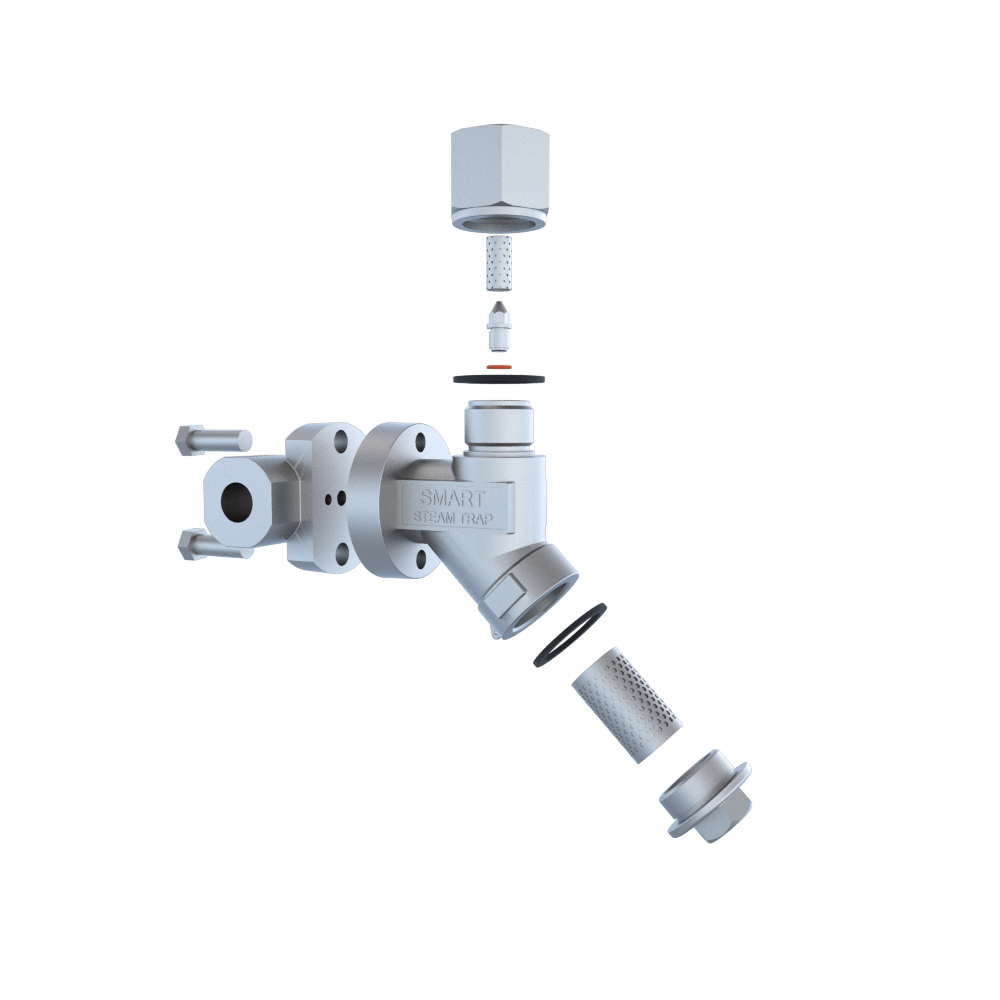

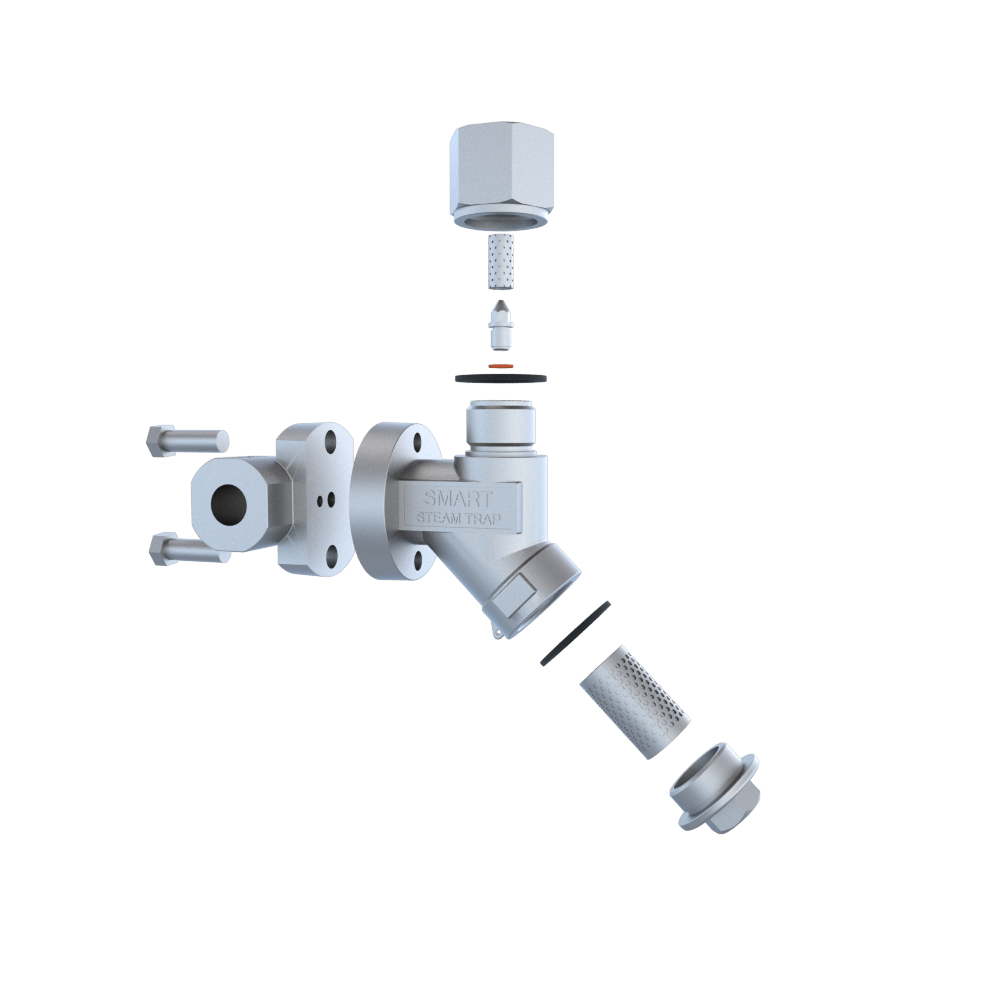

The SMART SVT UNI DN15/20 Venturi Steam Trap is designed for multipurpose applications from mainline drainage and trace heating, through small to medium size heat-exchanger process applications. The trap has integrated strainers and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and integrated strainers are via the top and bottom caps.

Connection

Screwed BSP/NPT

Socket Weld

Flanged

Applications

Line drainage (drip legs)

Trace heating

Process applications

Benefits

- No moving parts to fail.

- Integrated strainer system and a blowdown valve for easy strainer cleaning.

- Removable venturi insert for precise sizing.

- Simple in-line maintainability.

- Access to venturi insert and strainers via the top and bottom caps.

- 20-year performance and mechanical guarantee.

- A wide range of capacities.

- Custom face to face dimensions for flanged connections.

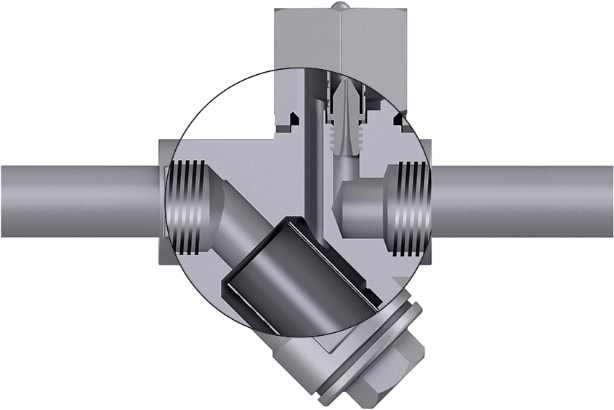

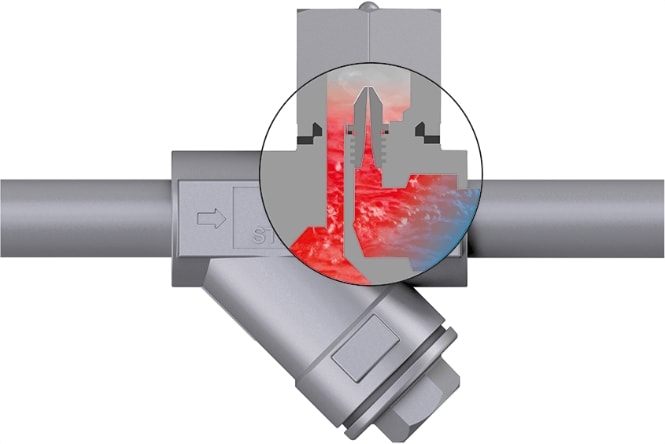

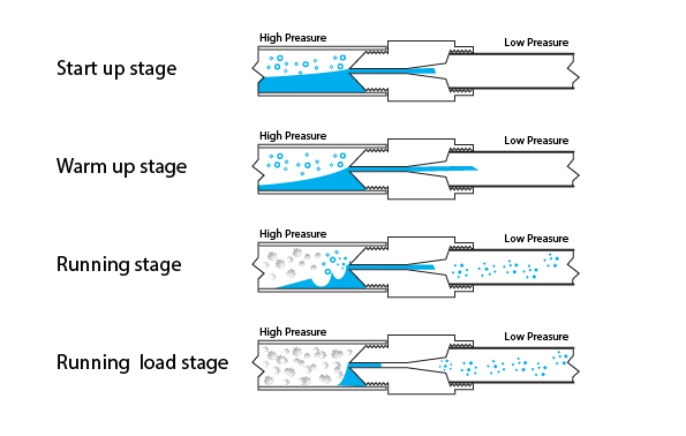

The overall capacity of the trap is comprised of two parts. First, a portion of the capacity is controlled by the diameter of the condensate removal channel. Second, a portion of the capacity is controlled by the back pressure that is generated inside the Venturi insert using flash steam.

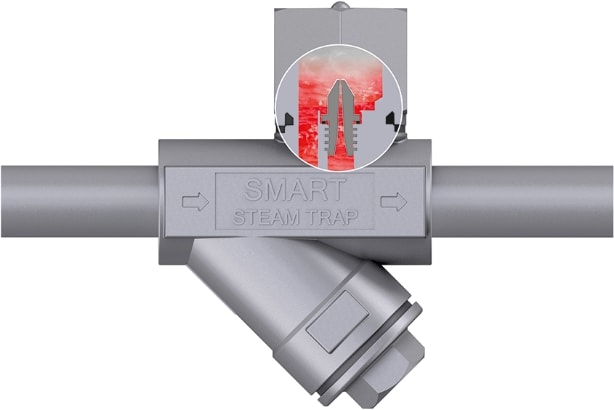

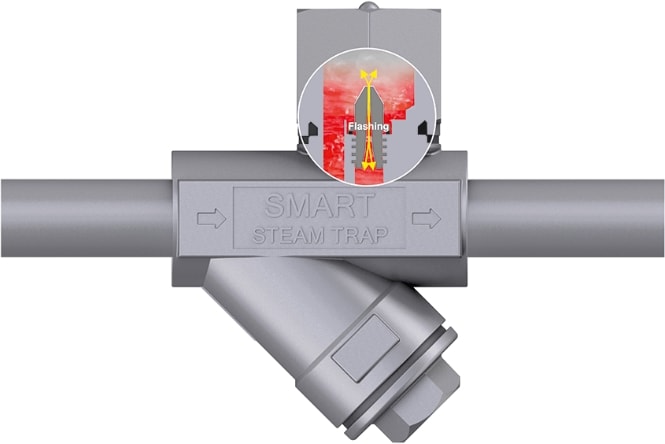

The replaceable insert has a reverse cone-shaped opening at the top leading to the Venturi section where the self-regulation process occurs based upon the physics of pressure change, a change in density, and energy conservation.

As the higher-pressure condensate enters the Venturi section, a small portion turns into flash steam and creates a barrier to the live steam. The flash steam is generated by the combination of the pressure drop across the channel and the difference in the density of the steam compared to the condensate.

The higher the pressure differential across the trap, the more condensate is converted to flash steam. The combination of the channel diameter and the production of flash steam give the Venturi trap its overall capacity and ability to handle varying condensate loads.

How does

it work?

Venturi Nozzle

Working Stages

The capacity of our Venturi Trap is a function of the insert channel diameter and the dimensions of the Venturi section. By utilizing the natural laws of physics, the change in the amount flash steam with the change in pressure, the capacity of the Venturi Steam Trap can adjust with the changes in process conditions. All our condensate removal valves utilize a custom modified Venturi Nozzle to separate the steam from the condensate.

The density of condensate is about 1,000 times greater than that of steam.

From the basic physics of a two-phase flow, we know that the heavier condensate phase will preferentially pass through the nozzle as compared to the lower density steam.

In a saturated steam system, a steam and condensate mixture is present at all times.

Smart Steam traps models

Let’s discuss your needs