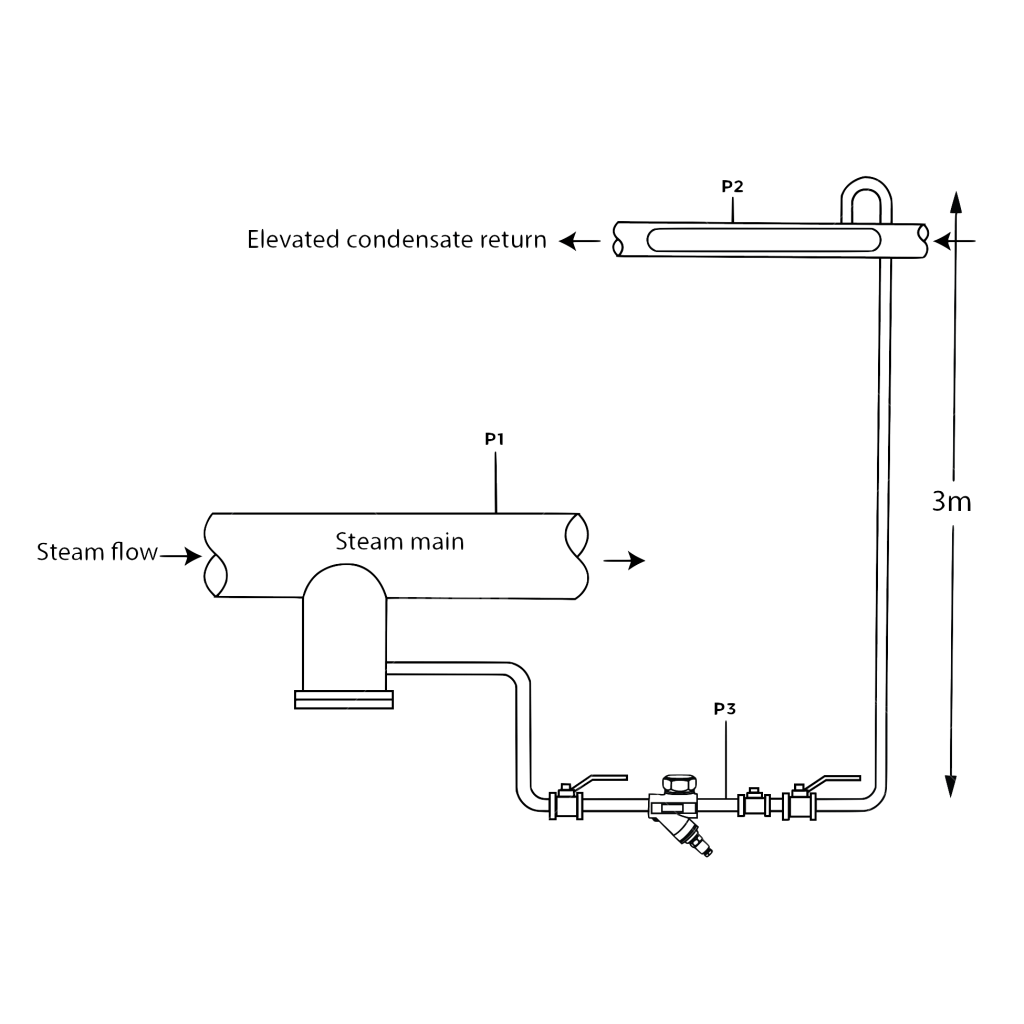

HOW DOES VENTURI STEAM TRAP WORK?

The overall capacity of the trap is comprised of two parts. First, a portion of the capacity is controlled by the diameter of the condensate removal channel. Second, a portion of the capacity is controlled by the back pressure that is generated inside the Venturi insert using flash steam. The replaceable insert has a reverse cone-shaped opening at the top leading to the Venturi section where the self-regulation process occurs based upon the physics of pressure change, a change in density, and energy conservation. As the higher-pressure condensate enters the Venturi section, a small portion turns into flash steam and creates a barrier to the live steam. The flash steam is generated by the combination of the pressure drop across the channel and the difference in the density of the steam compared to the condensate. The higher the pressure differential across the trap, the more condensate is converted to flash steam. The combination of the channel diameter and the production of flash steam give the Venturi trap its overall capacity and ability to handle varying condensate loads.

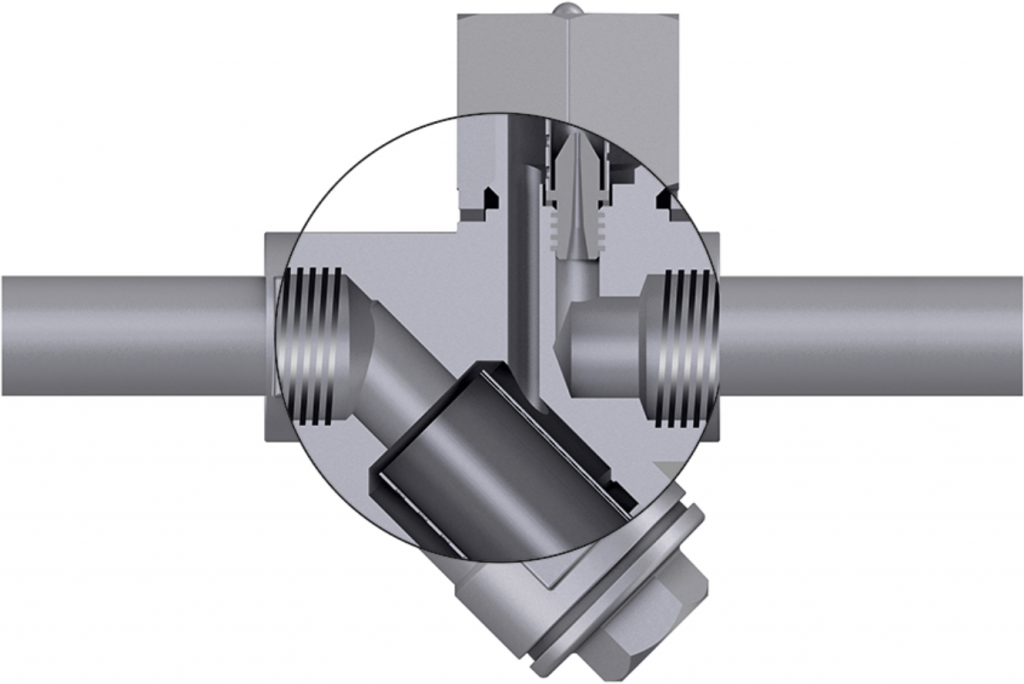

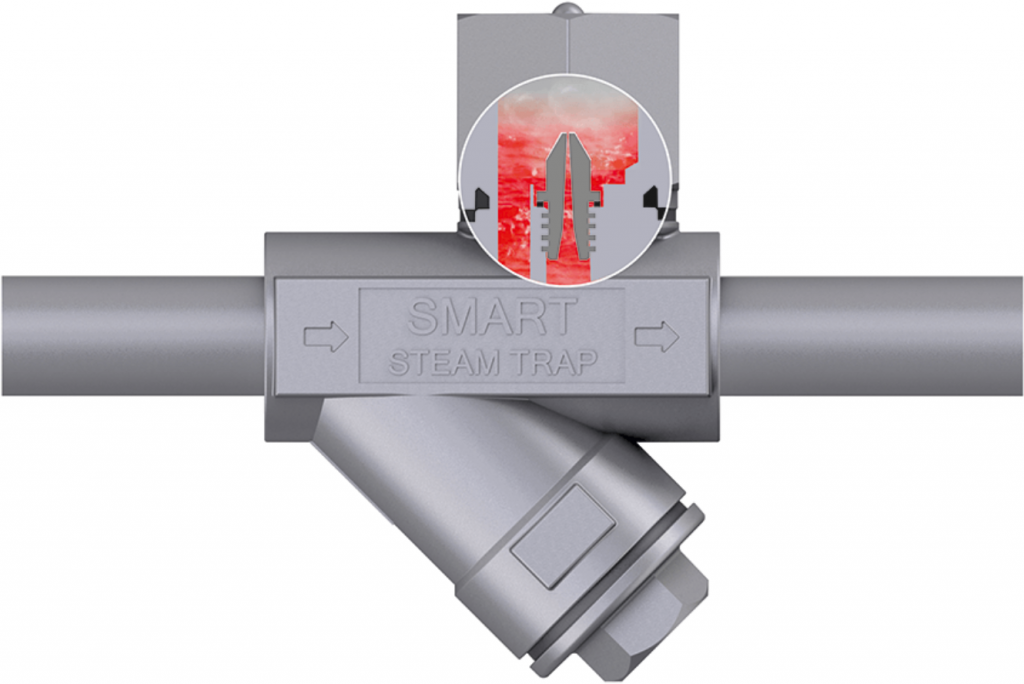

The overall capacity of the trap is comprised of two parts. First, a portion of the capacity is controlled by the diameter of the condensate removal channel. Second, a portion of the capacity is controlled by the back pressure that is generated inside the Venturi insert using flash steam.

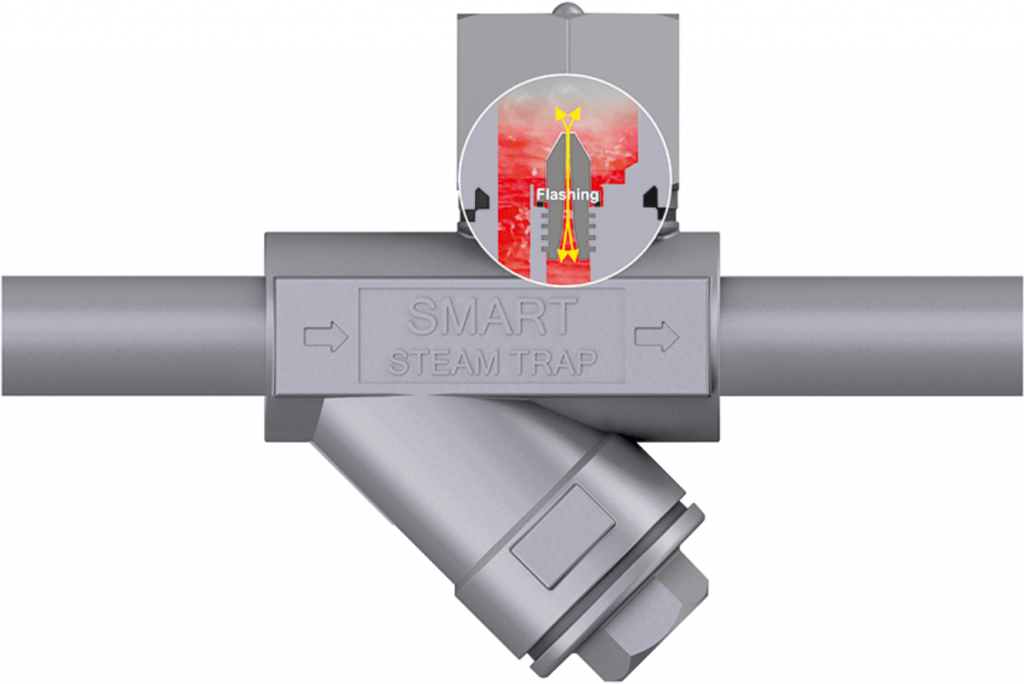

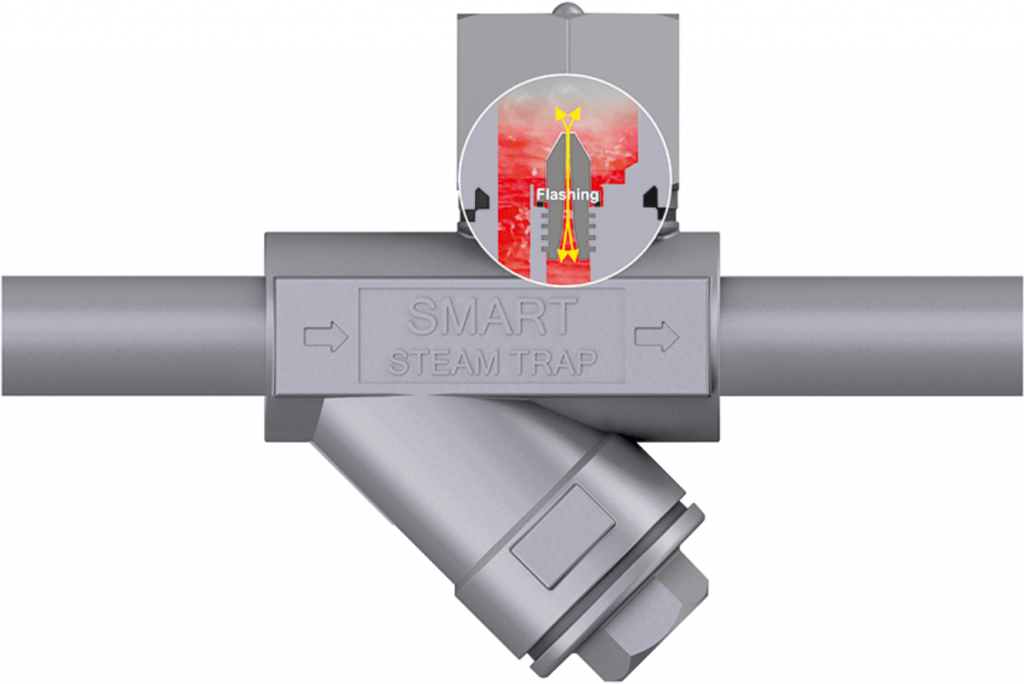

The replaceable insert has a reverse cone-shaped opening at the top leading to the Venturi section where the self-regulation process occurs based upon the physics of pressure change, a change in density, and energy conservation.

As the higher-pressure condensate enters the Venturi section, a small portion turns into flash steam and creates a barrier to the live steam. The flash steam is generated by the combination of the pressure drop across the channel and the difference in the density of the steam compared to the condensate.

The higher the pressure differential across the trap, the more condensate is converted to flash steam. The combination of the channel diameter and the production of flash steam give the Venturi trap its overall capacity and ability to handle varying condensate loads.

Let’s discuss your needs