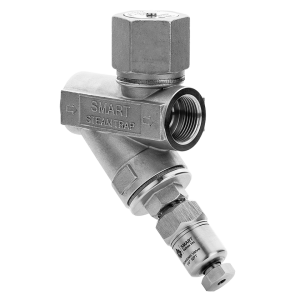

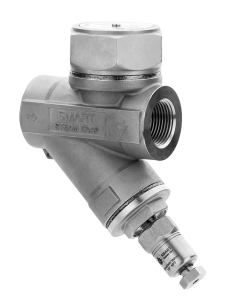

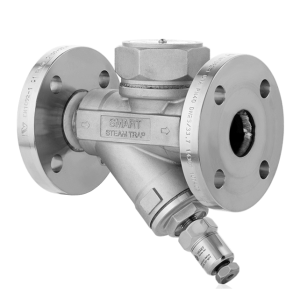

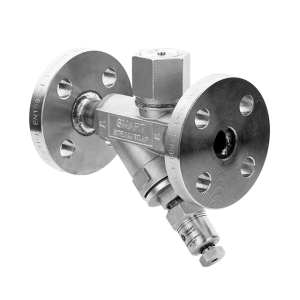

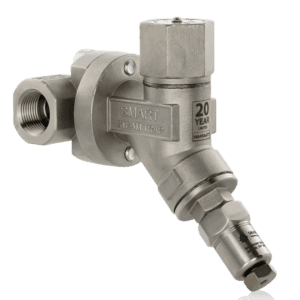

SMART VENTURI STEAM TRAPS

STCTM DN15/50

Description

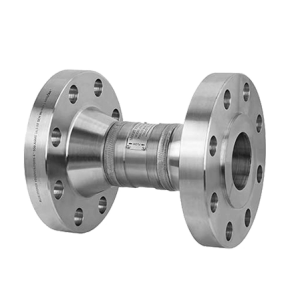

The SMART STC DN15-DN50 Venturi Steam Trap is designed for medium to high capacity industrial process applications with a wide range of pressure differential. The applications include heat exchangers, reboilers, process columns, etc with capacity up to 65 000lbs/hr or 30 000kg/hr. It is recommended that a strainer is installed upstream of the trap.

Connection

DN15(½”), DN20(¾”), DN25 (1”), DN40 (1½”), DN50 (2”)

Screwed BSP/NPT 304L

Applications

All process applications, like all kinds of heat exchangers, where condensate must be removed immediately after it forms.

Pressure /Temperature Limits

PMA (Maximum Allowable Pressure) 55 barg (797 psig)

TMA (Maximum Allowable Temperature) 270°C (518°F)

PMO (Maximum Operating Pressure) 50 barg (725 psig)

Guarantee

20-year product guarantee as per standard terms and conditions.

Benefits

- No moving parts to fail.

- All stainless steel construction; 20 to 30-year life expectancy.

- Wide range of capacities.

- 20-year performance and materials warranty.

- Permanent energy reduction, up to 20-30%; 1-2 year typical ROI.

- Significant lifetime labor and material savings.

- Inverted nozzle to deflect blockages.

Let’s discuss your needs

OTHER PRODUCTS

STCTM DN15/50

Request a quotation

Quantity

Specifications

Specifications