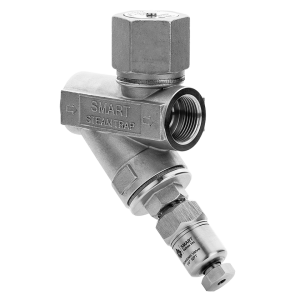

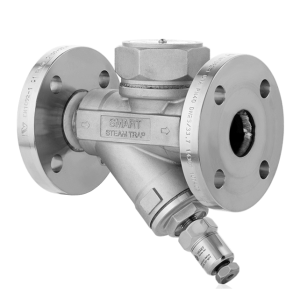

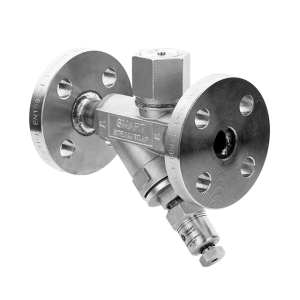

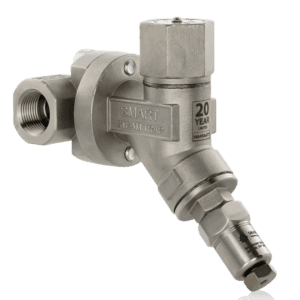

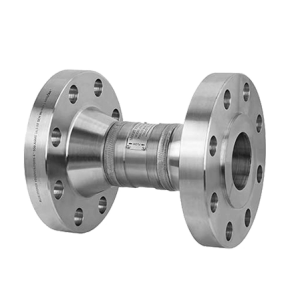

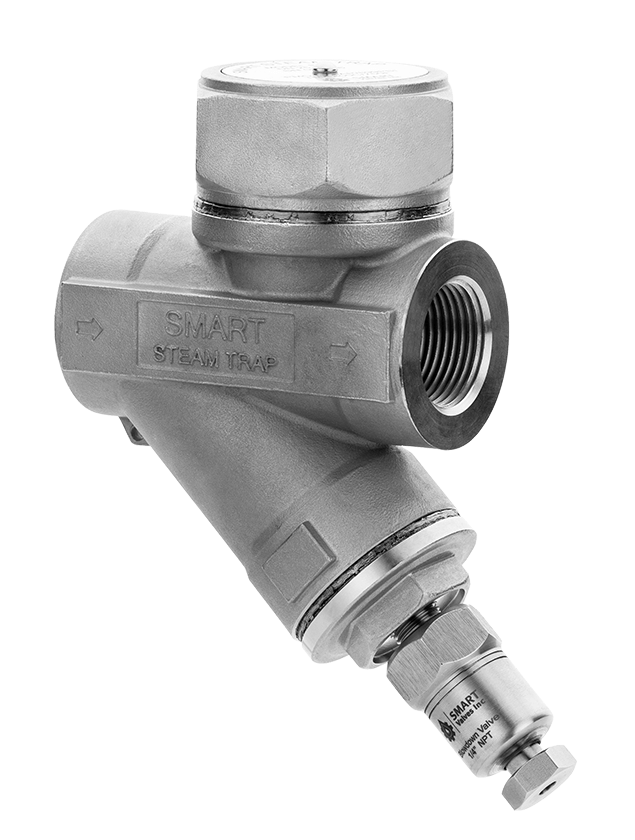

SMART VENTURI STEAM TRAPS

SVTTM DN25

Description

The SMART SVT DN25 Venturi Steam Trap is designed for multipurpose applications from mainline drainage and trace heating, through small to large size heat-exchanger process applications. The trap has an integrated bottom strainer with 25% increased capacity and a removable venturi insert. The body of the steam trap does not have to be removed from the line for maintenance purposes. Access to the venturi insert and strainer are via the top and bottom caps. SMART SVT™ model steam trap also comes with an integrated blowdown valve for periodic cleaning of the filter.

Connection

DN25 (1”)

Screwed BSP/NPT / Flanged/ Socket Weld

ASTM A351 CF3M

Applications

Line drainage (drip legs)

Trace heating

Process applications

Pressure /Temperature Limits

PMA (Maximum Allowable Pressure) 100 barg (1450 psig)

TMA (Maximum Allowable Temperature) 400°C (750°F)

PMO (Maximum Operating Pressure) 62 barg (899 psig)

Guarantee

20-year product guarantee as per standard terms and conditions.

Benefits

- No moving parts to fail.

- Stainless steel construction; 20 to 30 year lifetime.

- Wide range of capacities.

- 20-year performance and materials warranty.

- Permanent energy reduction, up to 20-30%; 1-2 year typical ROI.

- Significant lifetime labor and material savings.

- High capacity integrated strainer.

- Bottom cap for easy access to strainer.

- Inverted nozzle to deflect blockages.

Let’s discuss your needs

OTHER PRODUCTS

SVTTM DN25

Request a quotation

Quantity

How does it work

How does it work Specifications

Specifications